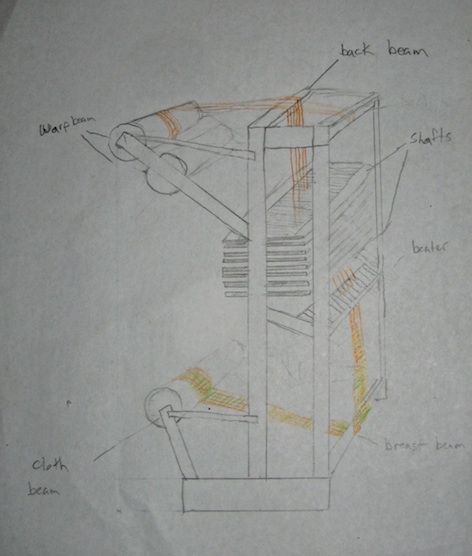

Here is a sketch of a loom I want to build. The skech isn't perfect, obviously the beater isn't quite right, but it is the general idea.

In order to put in large ceramic pieces (or metal or

other large items) I need to have a loom with a large working area, variable

tension and the ability to roll up or even simply gather the woven piece while

still weaving on the warp. In order to

achieve this, I am going to to create a tall tapestry style loom with 8-12

harnesses. There will be at least two warp beams. The cloth roller instead of

being on the front, or in front of the treadles will be in the back. This will

require a new way of moving the harnesses or changing how the treadles are

connected to the harnesses. In order to

have a beater that is in rest against gravity, it will need to be on hydraulics

or springs. Additionally, it will require a way to hold tension on the “breast

beam”; this will allow for the woven weft to either hang, or to have the woven

weft rolled on the cloth beam not control the tension. I also will need to have the harness/beater mechanism be able to move up and down on the loom, so that it would be feasable to create peices without moving the cloth or warp beams.

Anyone have any suggestions?

I was just pondering why the heddles are in the large harness frame and weather or not I need it to be that large. Realistically, I think it could be around 3" (10cm). Any thoughts on this?

Any ideas on what to use to slide the shafts? I was thinking cabinet drawer sliders or ball bearings

thanks,

Britta